Mechanical Properties of Al6061- Al2O3 Metal Matrix Composite Using Die Casting Technique

6061Al - Al2O3 Metal matrix composites are applied as conventional materials in the domain of aerospace, automotive and marine applications to enhance the physical properties. The present work aimed to prepare metal matrix composite using 6061Al as the matrix material. Particulates of Al2O3 with 40 μm were reinforced using die casting technique. Further level of reinforcement is being varied from 0-16wt% in steps of 4wt%. Microstructural characterization has been conducted for the resulting composites to check the homogeneous distribution of particles. Tensile properties of 6061Al - Al2O3 composite have been analysed. Effect of reinforcement on the tensile properties was studied carefully. Enhancement in tensile properties was observed by the addition of particles in to the matrix and a maximum strength was observed for the composite with 12% fillers. Incorporation of Al2O3 into 6061 enhances the wear resistance up to a loading level 12%.

Keywords: Al6061; Al2O3; Die- Casting; Mechanical Properties; Wear Test

Metal matrix composites (MMCs) are increasingly becoming attractive materials for advanced applications in the field of aerospace, automobiles, turbines, etc. The properties of matrix material can be improved by adding suitable fillers [1,2].

Die casting method is an effective and low-cost method to produce MMCs. Besides being simple, flexible, and attractive, as compared with other techniques, it allows the production of components in large quantity. Moreover, this type of processing is now in commercial use for the preparation of particulate Al-based composites [3]. Madeva, et al. developed an Aluminium based composite material by reinforcing Al2O3 using melt stir method [4]. There was an enhancement in the tensile and yield strength in the resulting composite material. It was also noticed that the hardness of the material increased by increasing the weight fraction of particulates. A fine and uniform morphology was also observed for the composites produced by Melt stirring method. Metal matrix composite of Al6061 reinforced with ceramics has been reported by Shaikshavali, et al. [5]. SiC was used as the ceramic particulate to reinforce in the matrix. Hardness of the composite showed an enhancement compared to the pristine Al6061. The addition of ceramic fillers into Al6061 improved the tensile and impact strength. A low-pressure die casting method was introduced by Chennakeshav and Essa to avoid the transport of clustered Al2O3 particles into the die cavity [6]. An increment in the fracture and yield strength with increase in the volume fraction of Al2O3. The formation of intermetallic particles such as Al5Cu2Mg8Si6 or Al4CuMg5Si4 reduces the ductility of the composite.

Hybrid composite of Al2O3 and graphite was prepared by reinforcing into Al6061 [7]. Hardness values were found to be increased by the addition of both the powders of Al2O3 and graphite into Al6061matrix. A significant improvement in hardness was observed for 1wt% added composites with equal propositions. The formation of a lubricating layer is a key factor that controls the wear behavior of these hybrid composites. Weight loss increases with increasing applied load and this is due to the pull out of graphite from matrix material and the presence of Al2O3 ceramic phase in the hybrid composite.

Mahalingegowda and Mahesh developed a composite material of Al2O3 reinforced Al6061 matrix [8]. Reduced porosity and uniform distribution of particulates can be seen in the microstructure studies. Tensile strength and compressive strength were increased with the addition of Al2O3. Composite of Al6061 alloy with Silicon Carbide and alumina was reinforced by Senthi kumar, et al. [9]. Composite shows superior to base Al6061 alloy in the comparison of mechanical properties. Comparatively better fatigue strength was noticed for composites than the unreinforced alloy. A fair and uniform distribution of Silicon carbide and alumina particles was highlighted in the SEM microphotographs. 6061Al-Al2O3 metal matrix composite has been prepared by stir casting method with 6, 9 and 12 wt% of particulates and evaluated the material properties [10]. Melt stirring method was adopted for the synthesize of these composites. A uniform distribution of particulates was confirmed from optical micrographs. It consists of primary D-Al dendrites and eutectic silicon. Enhancement in hardness and strength in terms of tensile and yield was observed for composites compared to the pristine material. Ductility of composite shows a reduced manner. An increasing trend was observed in the wear resistance of 6061Al composite material. Optimization of processing parameters is important to develop the material with more efficiency in case of casting of Aluminium alloys/composites. Dhanashekara, et al. extensively studied about the optimization of processing parameters for advanced materials [11]. According to them, the composite prepared by applying 100 MPa pressure exhibited better microstructural and mechanical properties. The size of particulate size is the main factor to decide the final strength of composites. Material with excellent properties was reported for materials having smaller grain size. Temperatures in the range 600 ºC to 700 ºC were the suitable one to cast Aluminium alloys. Mechanical properties of the alloys are enriched when fabricated through the squeeze casting technique, under controlled process parameters.

Himanshu, et al. reported a review article on stir casted Aluminium based metal matrix composites and according to their opinion, stir casting method can be successfully used to manufacture metal matrix composite with desired properties [12]. A combination of metal and ceramics is an easy way to improve the mechanical as well as thermal properties. Incorporating the particulates such as alumina, SiC, B4C etc. in aluminum improves the hardness, yield strength, tensile strength. Whereas ductility was reduced. Addition of graphite in aluminum increases the tensile strength and elastic modulus but hardness was found to be decreased. It shows a reduction in friction coefficient in case of tribological behavior. A limited works has been reported on hybrid composites by using modified stir casting method. Composite of 6061Al-Al2O3 was developed and characterized by Bharath, et al. [13]. Uniform microphotographs were obtained for 6 and 9 wt% of Al2O3 incorporated composites. The microstructure of the composites contained the primary -Al dendrites and eutectic silicon. Al2O3 particles were separated at inter-dendritic regions and in the eutectic silicon. The result shows an enhancement in hardness, tensile strength and yield strength by adding Al2O3 particulates. Reduction in ductility was also observed with increasing the percentage of Al2O3. The aim of the present work is to study the influence of microstructure (As cast conditions) and volume fraction of alumina reinforcement on the tensile properties of 6061 Aluminum alloy metal matrix reinforced with alumina (Al2O3).

6061Al alloy was selected as the matrix material for the present investigation and it was purchased from FINFY, Bangalore, India. Composition of 6061Al alloy is as shown in Table 1. The mechanical and physical properties of 6061Al alloy are depicted in Table 2 and Table 3 respectively. Particulates of Al2O3 with 40 micro meter size were purchased from Raghavendra Metallurgical, Bangalore, India. The properties of Al2O3 are listed in Table 4.

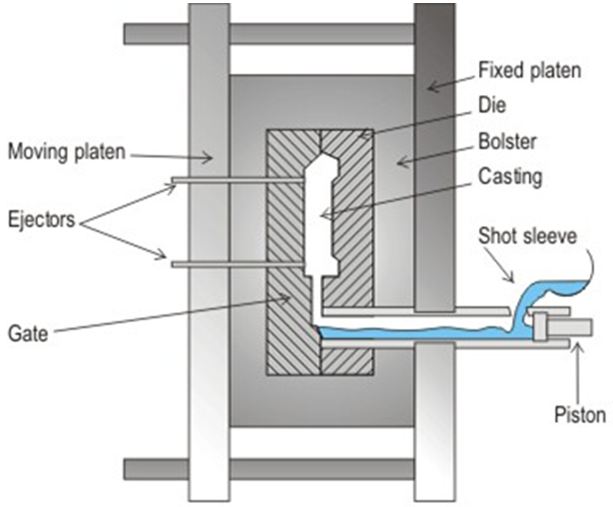

Figure 1 shows the experimental setup of high pressure Die Casting. In this technique, the mould is permanent and made of a metal such as cast iron or steel. Molten metal is injected at high speed and high pressure into a metal mould. It consists of two vertical platens on which bolsters are located which hold the die halves. One platen is fixed and the other can move so that the die can be opened and closed. A measured amount of metal is poured into the shot sleeve and then introduced into the mould cavity using a hydraulically-driven piston. Once the metal has solidified, the die is opened, and the casting removed. While pouring the molten metal into cavity, the temperature will be raised to 750 ºC. Thus, composite materials with different compositions (0, 4, 8, 12 and 16wt %) were achieved in the form of cylindrical shaped rods with diameter 30mm and a length of 300mm.

The tensile testing of the composite samples was carried out as per the ASTM E8 standard, by the help of computerized universal testing machine (Extensometer). The samples with diameter 16mm and Gauge length 165 mm were introduced for test with a cross head speed of 8mm/min. Machining of the samples were done as per the ASTM E8 standard. The average values of four test results were taken for the interpretation. Surface hardness of the samples was performed using Brinell hardness testing machine. Specimens were prepared for hardness test according to the ASTM E10 with length 20mm and diameter 20mm as shown in Figure 2.

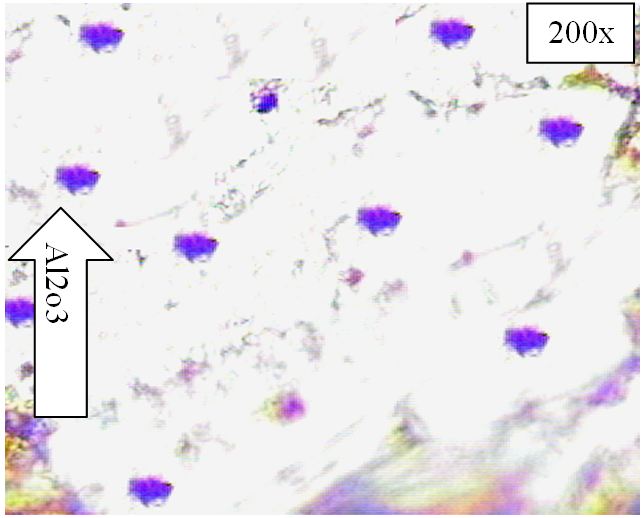

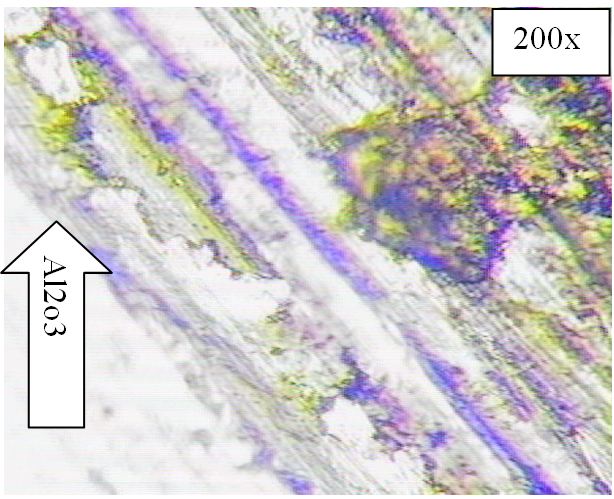

The effect of microstructure on the properties of a composite material was studied using computerized optical microstructure testing equipment with 200 x magnification. Specimen was prepared by using emery sheets and polishing machine.

Wear testing of the resulting samples was conducted with the help of pin-on-disc equipment. The specimen for wear test is as shown in Figure 3. Surface of the wear track on the specimen was cleaned thoroughly with acetone prior to test. Specimen was then weighed using a digital balance with accuracy of ±0.0001 gm. Further, the specimen was fixed on the pin holder of the tribometer for the test. Experiment has been conducted with a sliding speed of 300 rpm, track diameter 50 mm, load 3 kg, 4 kg and 5 kg for 5 minutes under room temperature. For Wear Test, specimens were prepared as per ASTM D785-08.

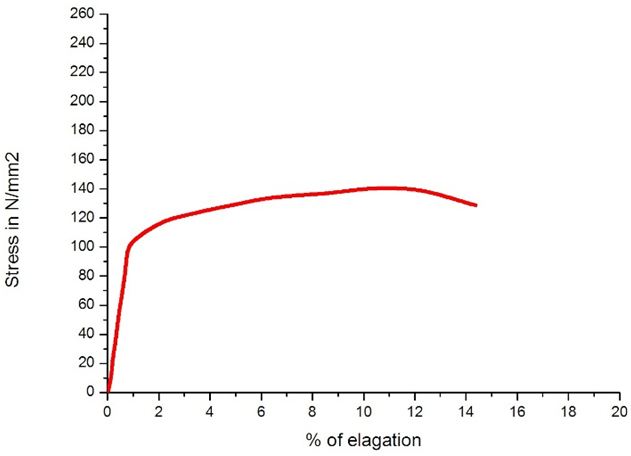

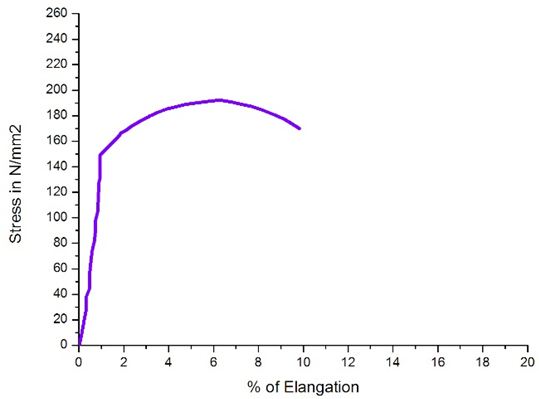

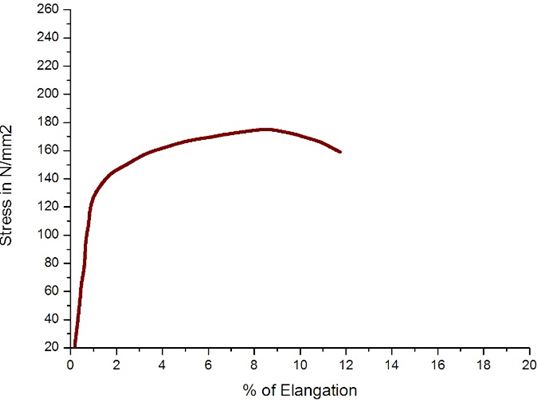

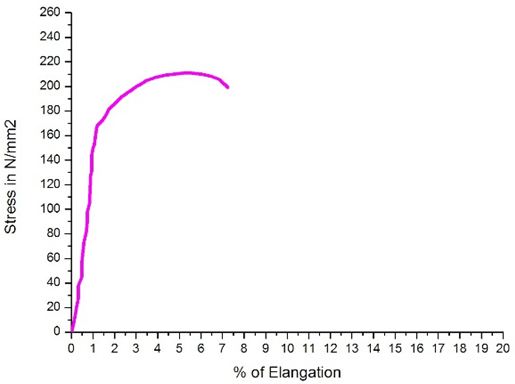

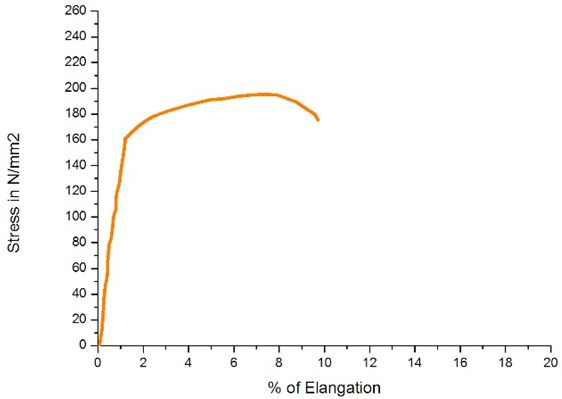

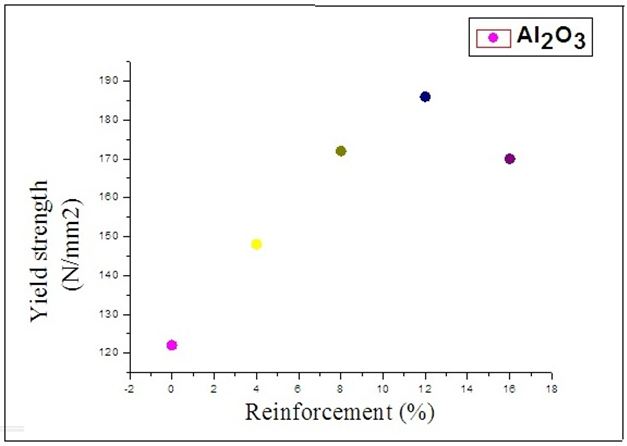

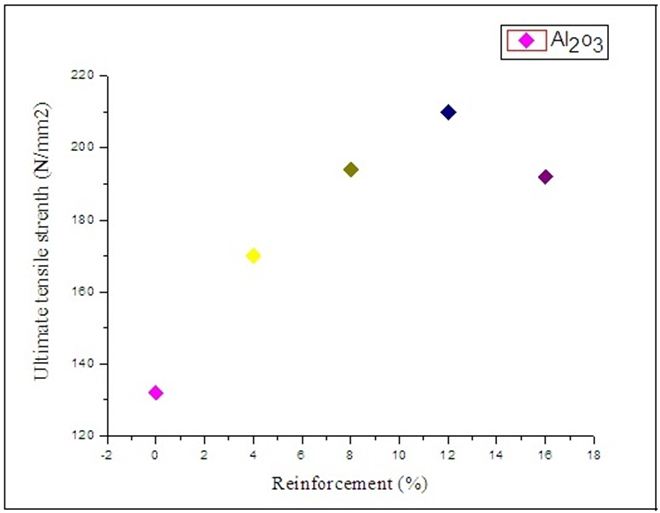

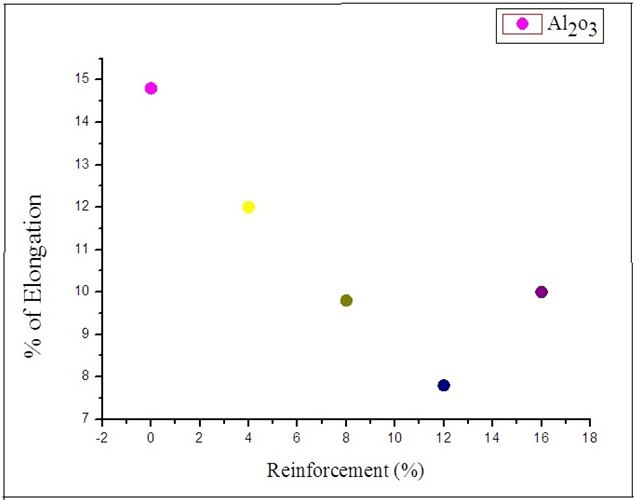

Stress-strain plot provides the information about the tensile properties of any material. Figure 4 shows the stress-strain curve of base material (Al6061). The yield strength, ultimate tensile strength and percentage of elongation of the sample are found to be 122 N/mm2, 132 N/mm2 and 14.8 respectively in case of sample without reinforcement. There is considerable change in the plot for composite materials compared to pure base material. Stress-strain plots of composite samples are as shown in Figure 5. Enhancement in all the tensile properties can be clearly seen in the figure. Addition of particulates increases the stability of base material. A reduction in elongation at break is observed by the addition of particulates. This is due to the interaction developed between matrix and filler. Many reports are available in literature on the improvement in stability in terms of tensile properties of aluminium alloys [14-16]. Mechanical strength of aluminium based composites has been drastically increased with the addition of suitable particulates in it.

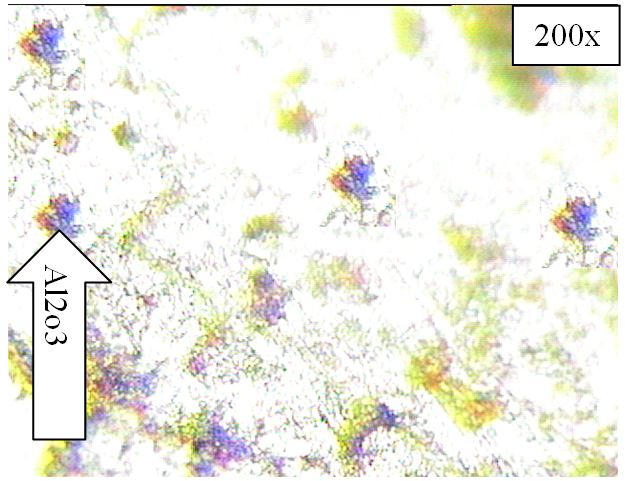

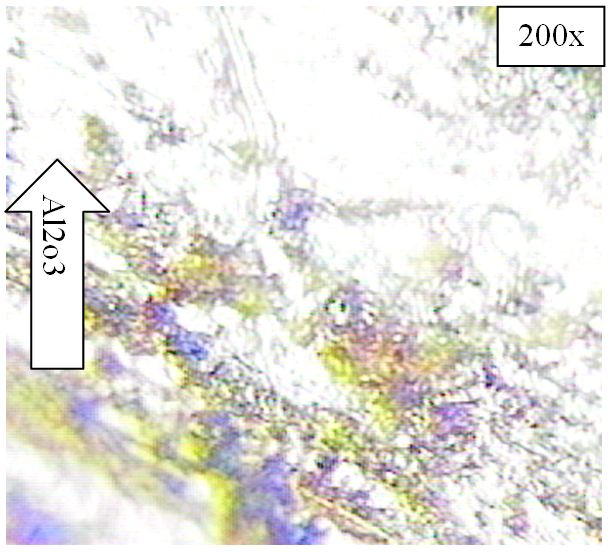

Tensile strength and hardness of the resulting samples were increased with increasing the percentage of particulates. It may start to reduce when the percentage of particulates reaches a particular level. Uniform distribution of the particulates increases the stability of composites by improving the interfacial interaction between matrix and fillers. At higher loading level, the interaction between particulates will be more compared to the interaction between matrix and filler. Therefore, it leads to the formation of agglomerates within the matrix. The material shows a reduction in tensile and hardness at higher loading level. It can be clearly seen in the microphotographs.

Tensile properties such as yield strength, tensile strength and elongation at break of the resulting composites for various percentages of particulates are as shown in Table 5. Yield strength and tensile strength values are increased gradually up to 12 % of particulates in the aluminium matrix. Further, the values found to be reduced. Agglomeration of particulates or reduction in the uniformity of dispersion reduces the tensile properties of the composites at higher loading level. Elongation at break can be related to the ductility of the material. Highly ductile material shows higher values in elongation at break and it reduces when the brittleness increased.

Brittleness at some portions of the composite material increases due the formation of agglomerates. Therefore, elongation at break reduces above 12 % filler in the aluminium alloy matrix (Figure 7). And also we can observe Yield strength, Ultimate Tensile strength and percentage of elongation of 6061Al-Al2O3 metal matrix composite in Figure 9,Figure 10 and Figure 11.

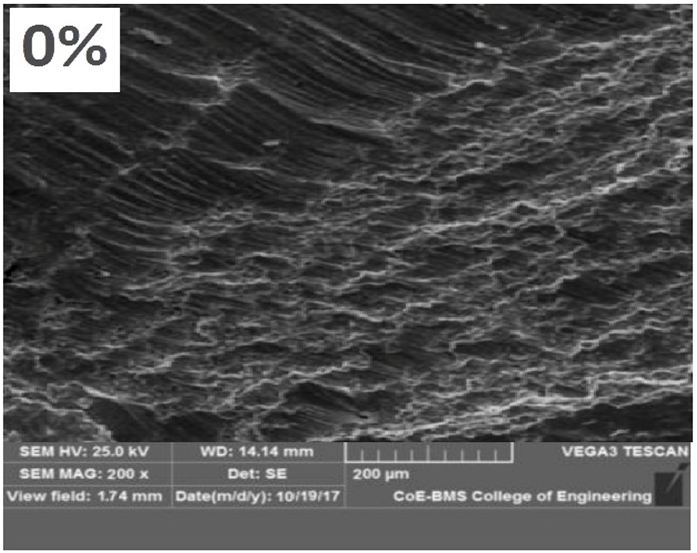

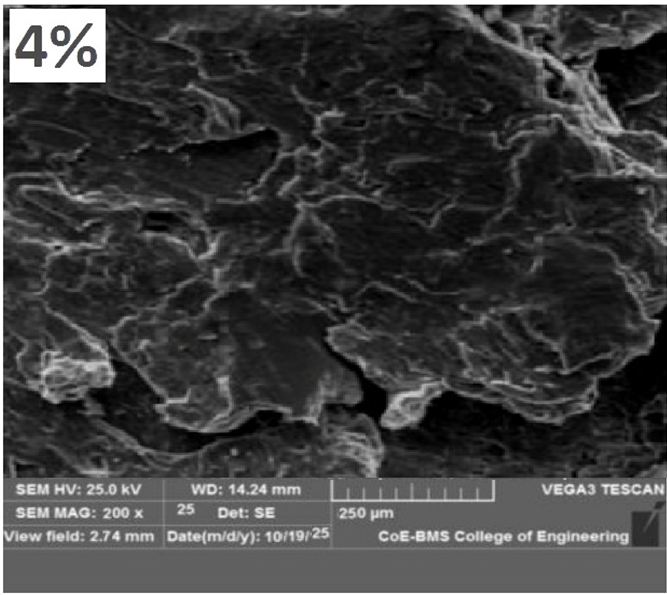

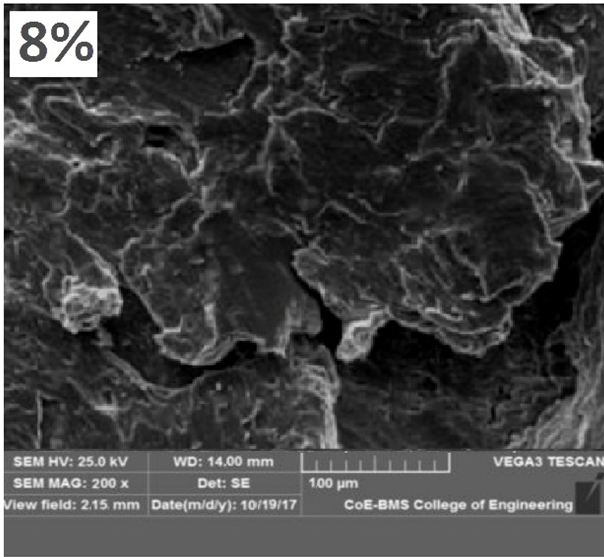

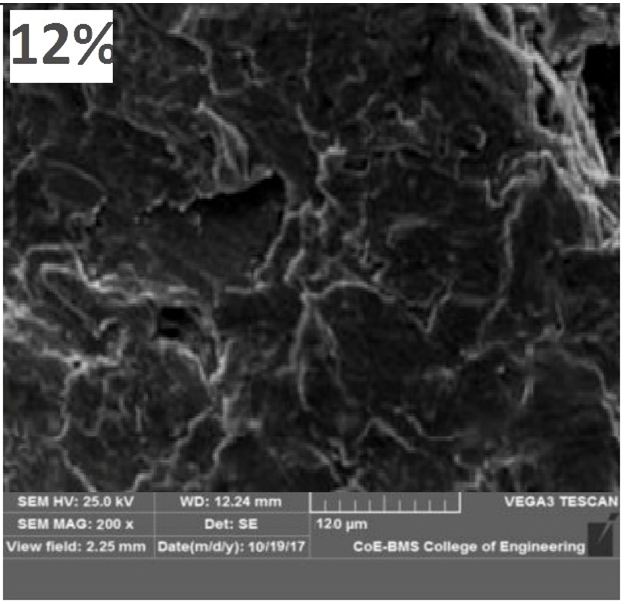

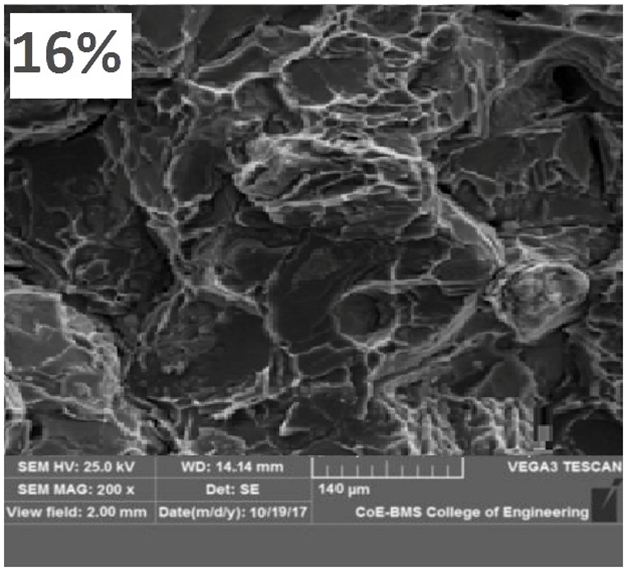

Figure 12-16 shows the microscopic photographs of 6061 Aluminum alloy metal matrix reinforced with alumina. A fine morphology is observed in all the composites and it indicates a better dispersion of particulates through out the matrix. Agglomeration occurs as the percentage of particulates crosses 12 %. Interaction between particle and matrix reduces and interaction between particulates and particulates increases. It leads to reduce the tensile and yield strengths above the mentioned composition.

Brinell hardness testing machine was employed to measure the hardness of the resulting composite materials. The hardness value has been calculated from the diameter of indentation. The variation of hardness on the addition of particulates into 6061Al is as shown in Table 6. 6061Al alloy is a ductile material and it exhibits more plasticity. The samples of composites are developed for only 40-micron sized particulates with various weight fractions. Hardness of the resulting composites increased with increasing the amount of Al2O3 particulates. Increase in interaction between matric and filler leads to enhance the hardness of composites. Therefore, the ductility of 6061Al decreases on reinforcing Al2O3 particulates. An increase of 11.42 % in hardness is noticed for 6061Al on incorporating 4 % (weight %) of Al2O3.

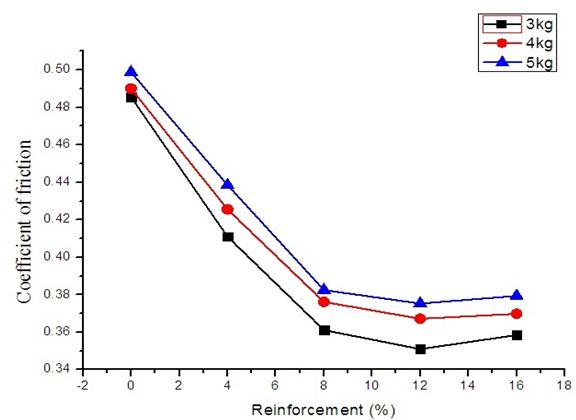

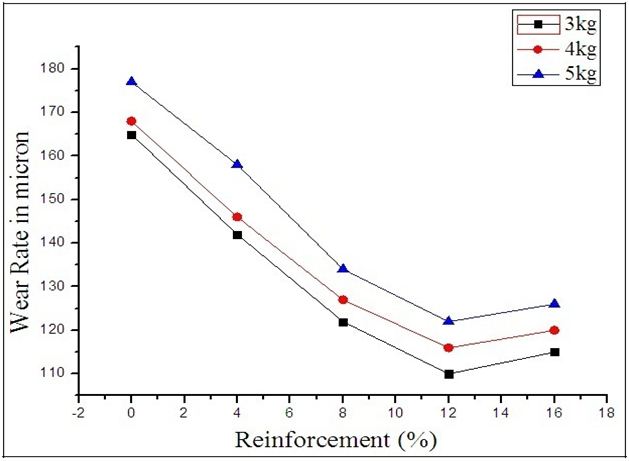

Aluminum–matrix composites are found to be excellent engineering materials due to their high specific strength. It shows superior wear resistance. Such type of material is applicable for the preparation of bearing material, brushes, contact strips etc. In the present investigation, an attempt has been made to study the dry sliding wear behavior of Al6061/Al2O3. Wear test on the resulting metal matrix composite material is conducted under three different applied weights of 3 kg, 4 kg and 5 kg for a constant slippery speed of 1.57 m/s. normally, reinforcement or filler loading strongly affects wear properties of the metal matrix composites positively. Figure 17 shows the variation of coefficient of friction for different loading levels of Al2O3 into Al6061 at various loads. Coefficient of friction is a measure of wear of materials. Al6061 alloy exhibits higher coefficient of friction compared to the other composites. This may be due to the ductile and softened nature of the pristine matrix. Addition of filler into Al6061 matrix increases the wear resistance of matrix. Formation of interaction between filler and matrix increases upon the addition of filler. Therefore, the resulting composite shows higher wear resistance and it increases with increasing the percentage of filler. A drastic reduction in the values of friction coefficient for lower loading levels can be seen in the figure. Above 8% of filler in the matrix, there is no considerable change in wear resistance. At lower loading levels, the filler particulates neatly disperse in the matrix and it shows higher wear resistance in Figure 18. Agglomeration of particulates in the matrix is responsible for it.

Figure (Figure 19-23) shows the SEM photographs of 6061 Aluminum alloy metal matrix reinforced with alumina. SEM photographs provide better information about the surface morphology of a material. Microstructural defect such as micro cracks blow holes and pits can be seen in the images. A fine morphology is observed in 12% alumina reinforcement composite and it is reflected superior mechanical properties.

Composites of Al6061 Aluminium alloy has been successfully prepared by reinforcing Al2O3 particulates of 40-micron size with various loading levels. Microstructure studies showed that the composite shows better dispersion of particulates at lower loading levels. Tensile properties and hardness of the composite exhibited an increasing trend upon the addition of particulates in the matrix. Wear resistance studies showed a positive impact on the addition of Al2O3 in Al6061 matrix. Finally, it can be concluded that the resulting composite material can be used to manufacture materials with higher stability.