Variation of Noise with Some Scanning Parameters for Image Quality Test in a 128 Slice Computed Tomography Scanner Using Catphan700 Phantom

Dose and image quality in diagnostic radiology is still of most concern in current research works. In computer tomography (CT), image quality can be affected by physical components of the scanner such as x-ray tube, detectors and data acquisition system. The choice of tube voltage (kVp), tube current (mA), pitch, slice thickness, Field of view (FOV), also have influence on image quality and dose. All these parameters contribute an amount of noise in the image produced by these systems. In order to maximize image quality and reduce dose, recent CT design have incorporated Automatic tube current modulation (ATCM) techniques to regulate mAs and maintain image quality. However, there is still a variation in the in the level of noise produced by these systems which is due to the fact that different manufacturers apply ATCM techniques differently. In this letter, the variation of noise with mAs, slice thickness and spatial resolution have been investigated in a 128 slice CT scanner using catphan700 phantom. The study shows that, a linear relationship exist between range of noise, mAs and slice thickness. However, the range of noise was found to be independent on spatial resolution of the system. Future works on the variation of noise with mAs, slice thickness and spatial resolution using different methods and different scanners is recommended.

Keywords: CT Noise; mAs; Slice Thickness; Spatial Resolution

The metrics of image quality in diagnostic radiology can be affected by the physical components of the system design. These include the gantry, x-ray tube, detectors and data acquisition system. Nevertheless, almost all other scanning parameters that can be used to describe image quality depend heavily on the signal to noise ratio (SNR) of the image. Increasing the SNR leads to an increase in image quality [1]. But an increase in SNR may significantly increase patient’s dose.

In Computed Tomography (CT), image quality and dose are two key areas that are closely linked together. For every CT examination, a categorical preference must be made for some scanning parameters. These include the X-ray tube voltage (kVp) and X-ray tube current (mAs). The quality of CT image and dose (mAs) received by the patient is influenced by the choice of kVp and mAs [2].

Recent, advances in CT technology and its applications in the clinical environment has resulted in an increase in number of CT examinations. As a result of these advances, there are variations in the quality of images produced by CT scanners. Some CT scanners have been designed with Automatic tube current modulation (ATCM) techniques in order to regulate mAs and maintain image quality for patients of different sizes and shapes. However, the level of noise in these scanners is questionable due to the fact that different manufactures apply the ATCM differently, resulting in the variation in image quality [3].

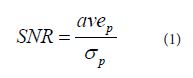

CT noise is determined primary by the number of photons contributing to an image. Statistically, image noise can be calculated from the standard deviation of CT number or pixel intensity values in a physical uniform region. The variance (standard deviation) for pixel values decreases with image noise [4,5]. Noise is measured by comparing the level of desired signal (photons) to the level of background noise (pixels deviating from the normal). This is known as signal to noise ratio (SNR). The higher the ratio, the lesser the noise present in the image. SNR is calculated as the ratio of average pixel value, avep, to the standard deviation of the pixel values, σp.

The number of photons utilized in an examination has a direct relationship with mAs, slice thickness, patient size and spatial resolution [6]. In this letter, we provide the variation of range of values of CT noise with mAs, slice thickness and spatial resolution using Catphan700 Phantom on a CT scanner as a follow up information reported in [7]. The scanner under investigation is an Aquilion 128 slice CT scanner manufactured by Toshiba Company (Toshiba Aquilion 128 CXL Edition, manufactured in the city of Otawara-shi, located in Tochigi state in the country of Japan).

Catphan700 phantom is a diagnostic imaging tool specially designed for comprehensive evaluation of axial, spiral, multi slice, cone beam, and volume CT scanners from the point of view of maximum performance [8].

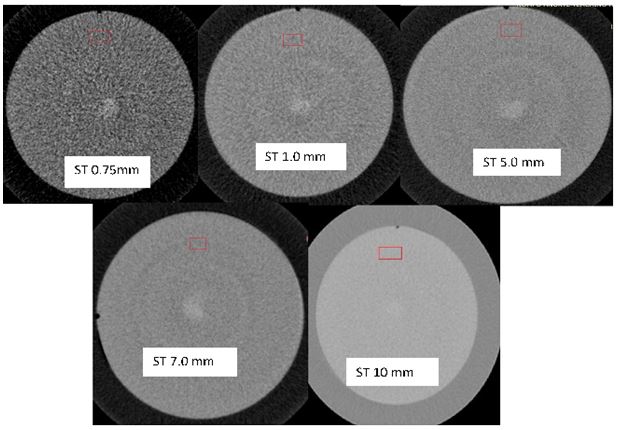

In order to determine the effect of noise with slice thickness, by varying the slice thickness (from 0.75 to 10 mm) using the head protocol (kV 120, FOV 150, Pitch 1.01) different images were obtained by scanning module CTP712 of the Catphan700 phantom. Using a region of interest (ROI) of 1000mm2, pixel values for all the DICOM images were obtained and measured from the reconstructed images of module CTP712 of the Catphan700 phantom with ImageJ Software (Figure 1).

The scan time and mA were merged together as mA x s, or mAs since they both affect noise. The noise was measured by calculating the standard deviation in the ROI. Also, the SNR was calculated from eqn. 1 above.

Theoretically, image noise (σ) is nearly inversely proportional to the square root of slice thickness as (h)1/2. This means that patient dose could greatly be affected by ultimately changing the slice thickness. Therefore, a retrospective reconstruction of images with different slice thickness will result in change in the magnitude of noise [9]. Varying the slice thickness changes the width of the beam reaching each detector.

From the study, it was realized that, a linear relationship exist between the slice thickness and the number of photons (mAs). The measured slice thickness, ST≈0.054*mAs as the slice thickness increases, the number of photons (mAs) used to produce an image was found to also increase. This decreases the standard deviation (SD) and thereby increases the SNR in the image. Table 1 shows the variation of slice thickness with image mAs and standard deviation. As the slice thickness was varied (increased) from 0.75 to 10 mm, the standard deviation (image noise) was found to decrease from 7.237 to 2.824 respectively. This may be attributed to the fact that thicker slices uses more photons, have better SNR and have the ability to reduce noise level in an image than thinner slice.

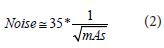

From the study, the image noise (SD) was found to be inversely related to the square root of mAs by a factor of 35 as shown in eqn (2) below.

This means that, in order reduce noise by 1/2 of the original, the mAs must be increased by 4 folds. Since reduction of noise relates inversely with image quality, it is usually recommended that, the medical problem under study should be used to determine the level of noise and image quality. We may also add here that, standard deviation alone cannot fully account for the noise in an image. For this reason, the operator can vary other factors such as kVp, filtration, pixel size, detector efficiency and interpolation scheme, so that standard deviation is equal between images since the perception of noise is different.

Also, the range of noise values was investigated against spatial resolution of the CT scanner. The spatial resolution was measured by calculating the Modulating Transfer Function (MTF) from scan images of module CTP682 of the Catphan700 phantom. Using different reconstructed images from slice thickness 0.75, 1.0, 5.0, 7.0, and 10.0 mm, pixel values surrounding the image of 0.18 mm tungsten carbide bead in the CTP682 module were obtained as described in the Catphan700 instructional manual [8]. The line spread function (LSF) along the x-and y-axes were determined by measuring the average pixel values of point spread function (PSF) in the horizontal and vertical direction respectively using the head protocol. The MTF was then calculated by taking the Fourier Transform of the LSF data using Matrix Laboratory (MATLAB) software (MATLAB software version R2012b, RadiAnt DICOM Viewer, Poznan, Poland).

Theoretically, when the spatial resolution is increased by reducing the slice thickness, the resultant effect is an increased in image noise [10]. From Table 1, the spatial resolution is generally greater (with higher 10% MTF values) in thinner slices than thicker slice thickness. Despite the high level of noise present (recorded) in the image of thinner slice thickness, the spatial resolution is better seen in the thinner slice than images of thicker slice thickness. The findings in this letter conform to the results reported by several researchers in establishing a relationship between noise, slice thickness and spatial resolution using different methods. In one of the results reported, 1.0 mm (thinner) slice thickness has proven to produce the best spatial resolution with more accurate diagnostic information than thicker slice thickness [11]. Rubinstein, et al. also demonstrated that, there is an increase in the diagnostic accuracy of fractures in odontoid process with thinner slice thickness [12]. In a multiplana reformation studies, Jung, et al. used 1.25, 2.5, 3.75, and 5 mm slice thicknesses to quantify the performance of CT. He found that, thinner slice thicknesses result in better image quality [13].

Although in this study we did not find any specific trend with how noise varies with MTF, images of smaller slice thickness showed higher 10%MTF values than images of bigger slice thickness. This is due to the fact that, thinner slice attenuates photons lesser as compared to thicker slices, and therefore allows more photons to reach the detector element of the CT device. Images of smaller (thinner) slice thickness provide better diagnostic information with improved visibility of smaller lesions due to decreased partial volume effect [14]. Hence from the study, we may conclude that, thinner slice thickness are able to resolve objects in images of CT better as compared to thicker slice thickness despite the considerable noise present in their images.

In this letter, the variation of noise with slice thickness, mAs and spatial resolution have been investigated. Slice thickness was found to heavily depend on image noise and mAs, with greater noise observed in images of thinner slice thickness than images of thicker slice thickness. Image noise (standard deviation) decreases with an increase in mAs and slice thickness. However, spatial resolution was found to be linearly independent on slice thickness, with no specific trend observed. Despite the high level of noise recorded in images of thinner slice thickness, images of thinner slices thickness was found to contain better diagnostic information (with higher 10%MTF values) than images of thicker slice thickness. Further works on the variation of noise on mAs, slice thickness and spatial resolution on different scanners are recommended for future studies using different methods. The results of the study could serve as a guide in quality control procedures in CT centers.

This work was supported jointly by the Department of Medical Physics under the School of Nuclear and Allied Sciences, University of Ghana and Ghana Atomic Energy Commission.