Briquette from Coffee Husk

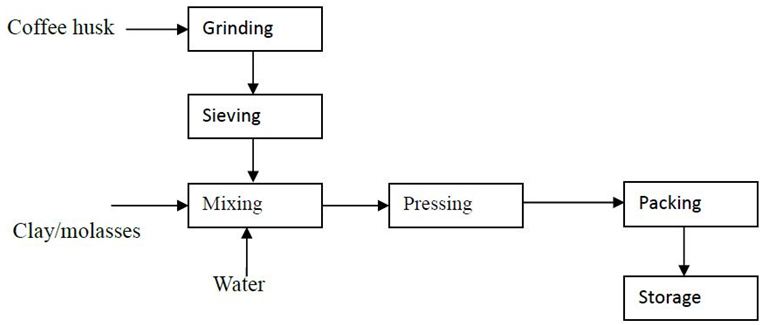

In Ethiopia, to about 3,300,000 tons of surplus coffee, cotton, wheat and barley residues are produced annually though not all are economically accessible; Even the much-reduced figure of those residues which arise from centralized state-farms, put at about 600,000 tons, is large enough to make a significant contribution to the Ethiopian energy economy. Briquetting is the process of conversion of agricultural waste into uniformly shaped briquettes that are easy to use, transport and store. At present, Coffee husks are an excellent material for briquetting available with 10 percent moisture content. This study aims comparing briquettes produced from coffee husk-molasses and coffee husk-clay, assessing the briquetting of biomass improves its handling characteristics, increases the volumetric calorific value, reduces transportation costs and makes it available for a variety of application and go through assessing the recent binder less briquetting technology.

Keywords: Briquette; Coffee Husk; Molasses; Clay

In 2003/04-2008/09 coffee was cultivated by three million farmers on a total of 308,000 ha, which is only 2.8 percent of total cultivated area. However, the share of area cultivated for coffee increased by 12.3 percent per year from 2003/04 to 2008/09. In 2008/09 337 thousand ton was produced, this is 1.3 percent of total production; 19 percent of total coffee output was produced by large farms. Coffee is Ethiopia’s major export product, and Ethiopia is the world’s fifth producer of coffee [1].

A project about development of a technology for combustion of coffee pulp from the Swiss Center of Appropriate Technology and Social Ecology CATSE (Okozentrum Langenbruck) had shown in 2010, that combustion of dried coffee pulp cannot be completed successfully in practice, excessive smoke development and early extinction of the fuel result [2]. However, combustion is only feasible under special laboratory conditions.

Depending on the amount of coffee pulp in the husk, this leads to the mentioned uncomplete combustion of coffee husk when the waste piles are set to fire. 6/49 from the mountain rainforest of Kafa region originates the fair-trade and organic certified Kafa wild coffee, sold in Switzerland and Germany. In the Kafa Forest Coffee Farmers’ Cooperative Union, 26 cooperatives are affiliated with approximately 6,000 small farmers. They process and market mainly sun-dried coffee from Kafa Forest. By collecting and selling wild coffee, coffee farmers of Kafa achieve a long-term income from the rainforest. But so far, the residues from the sun-dried coffee production has not been used but is burned in piles in order to get rid of coffee husk waste.

Even the much-reduced figure of those residues which arise from centralized state-farms, put at about 600 000 tons, is large enough to make a significant contribution to the Ethiopian energy economy [3]. Briquetting is the process of conversion of agricultural waste into uniformly shaped briquettes that are easy to use, transport and store. At present, Coffee husks are an excellent material for briquetting available with 10 percent moisture content [4]. Ethiopia heavily biased towards wood consumption, particularly in the household sector. Demand for wood and wood products, particularly charcoal which is the fuel of choice in many urban areas, is often growing and deforestation is a potential problem.

The goal of this study is comparing briquettes produced from coffee husk-molasses and coffee husk-clay, assessing the briquetting of biomass improves its handling characteristics, increases the volumetric calorific value, reduces transportation costs and makes it available for a variety of application and go through assessing the recent binder less briquetting technology [5].

The general objective of the study is comparative evaluation of physic-chemical parameters of coffee husk briquettes by using molasses and clay as a binding agent compressed through piston press.

The specific objective of this project is just to show the way how briquettes can:

➢ Reduce the potential problems of deforestation in serving as substitute for fuel wood as of it is alternative source renewable energy

➢ Generate information regarding to coffee husk waste-wealth.

The coffee husks are relatively very light with bulk densities ranging from 100 to 140 kg/m³). Because of their bulky nature these are normally stored in the open area. Depending upon the availability of supply, feed material for 6-14 days should be stored.

All unwanted materials or large biomass waste are removed to ensure that all the feedstock is of the required size. Screens may be employed to avoid contamination by extraneous materials like stones and steel pieces etc. and the screen mesh should be based on the largest size of the feed.

The coffee husks should be crushed to small pieces to about 5-8 mm size with 10-20% fines so as to enhance their workability and compactness. Hammer mills are employed to reduce the particle size of the feed material. While many types of crushing and grinding equipment are available in the market, for biomass materials, hammer mills are considered the most suitable because of their availability in various sizes.

The addition of heat benefits by relaxing the inherent fibers in the coffee husks and apparently softening its structure resulting in release of the organic matter bonding or gluing on to the surface. This phenomenon is also known as sweating the biomass.

This process is done in situations where you want to use a range of different feedstock to optimize the burning characteristics of the final fuel. For example, biomass materials with high ash content could be mixed with biomass material of low ash content. Biomass with low energy content such as papers can be appropriately mixed with those of high energy content. This helps to attain the right quality (long burning period, non-smoking and odor free) that will make briquettes competitive in the market.

An appropriate binder, molasses and clay are added and mixed with the coffee husk thoroughly. This enhances the compactness of the biomass material and prevents them from falling apart. Water is usually added to the feedstock to make them loose and easy to work on. Some biomass materials require to be soaked in water for two days to ensure that they are soft enough to work on.

Densification represents a set of technologies for the conversion of biomass into a fuel. The technology is also known as briquetting and it improves the handling characteristics of the materials for transport, storing etc. Finally, the feedstock is compacted by briquetting machine resulting the briquettes those will need to be left to dry.

Coffee husk samples were collected and dried to a moisture content of 10%. The coffee husk was then commutated to a screen size of 3 and 6 mm fitted. The milled husk was graded to different particle sizes by screening through mesh of varying sizes. Moisture content of the graded coffee husk was regulated by adding known quantities of distilled water to the samples followed by mixing and storing in air-tight bags for 48 hours to allow for uniform distribution of the moisture. Different proportions of sugarcane molasses or clay were mixed with coffee husk. The mixture should be well mixed to give a consistent material for compression into briquettes.

Firstly, 2 kg of coffee husk with 6 mm particle size have been measured. 40% of which was fine particle and then mixed with 900 ml (45%) binding agent (molasses/clay). 1 kg sample were taken and filled in a metal container with cylindrical shape having volume of 0.002 m3. The briquette samples were made by compressing the coffee husk-molasses and coffee husk-clay mixture in a pressing machine. After compression, the sample pushed out of the cylinder. The samples were then dried in a drier at a temperature of 60 ºC. After well dried, the volumes of the briquette samples were measured and similar procedures were followed for smaller sized particles altering with 45% and 25% binding agents.

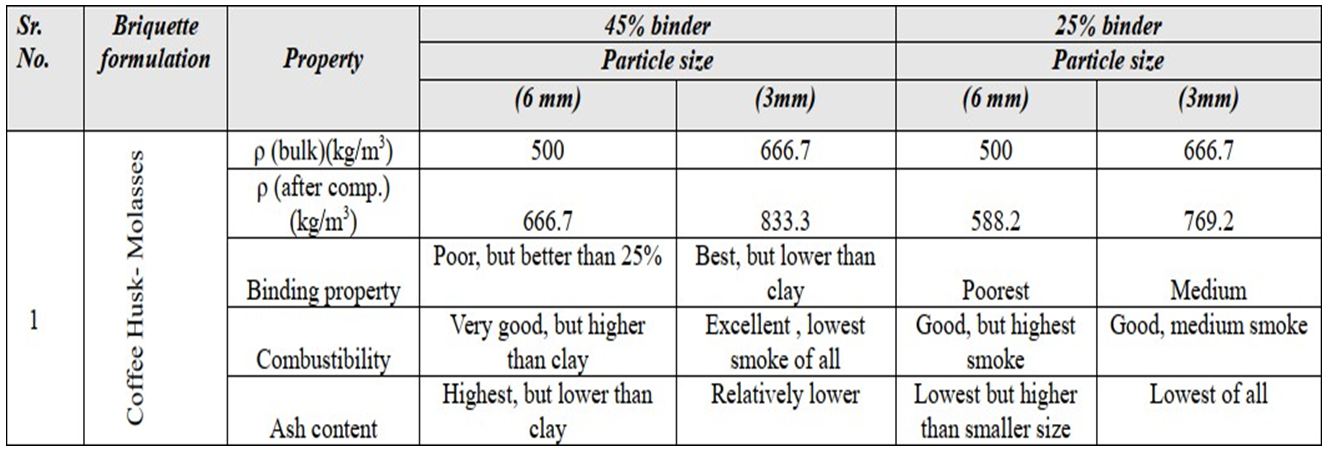

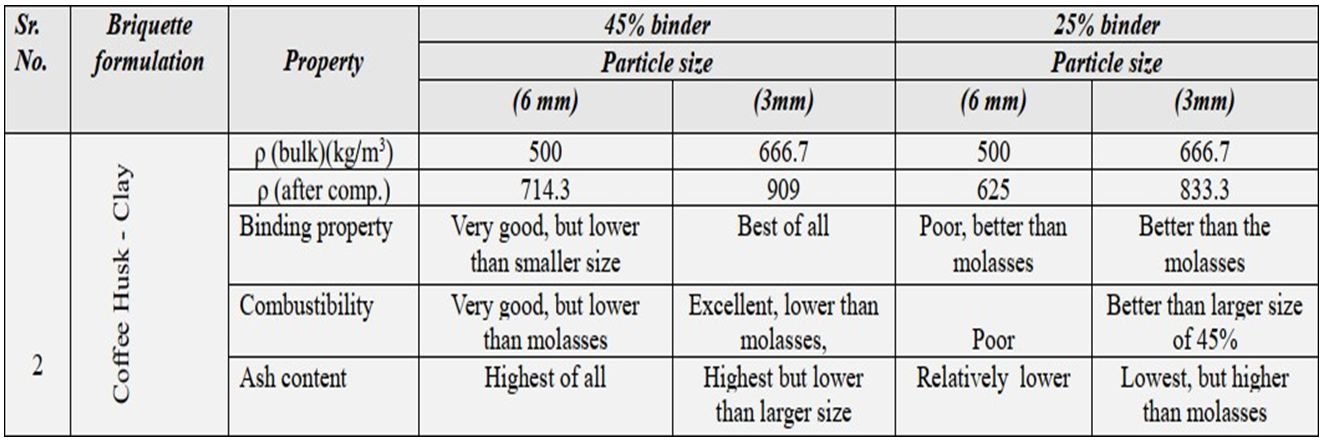

The experimental observations are summarized in the Table 1 and 2.

The density of the larger particle size (6mm) with 45% molasses and clay is found to be 666.7kg/3 and 714.3 kg/m3 respectively and the densities of the smaller particle size (3mm) with 45% binder are found to be 833.3 kg/m3 and 909 kg/m3 and also for larger and smaller particle size with 25% both binders are found to be 588, 625, 769.2 and 833.3 kg/m3 respectively.

An experimental result indicates that there is no significant difference between the values of the bulk densities of the sample with 25% and 45% of binder. The factors that affected density significantly at constant pressure were found to be binder content and the particle size.

The quantity and type of binder was found to be the most significant factors affecting the density of the briquettes followed by particle size. As the density of the briquette increases the combustibility also increases for the same binding agent.

The experimental result show that the ash content of the briquettes produced by coffee husk-clay is higher than that of coffee husk-molasses. This is why the clay comprises of unburned mater like, sand. Clay has better binding capacity than molasses but what matter is that the lower combustibility and higher ash content.

Previously, employed technologies required binders in the production of briquettes from agro- waste. Here we are going to introduce currently available screw extruder technology, however, use the BINDERLESS technology, which is found to be very economical.

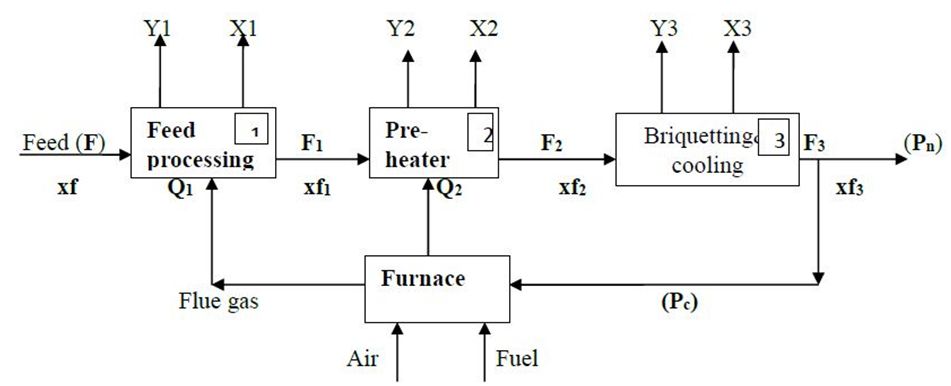

Before a material and energy balance can be carried out, it is first necessary to decide on an operating system to form the basis of the analysis as represented in Figure 2.

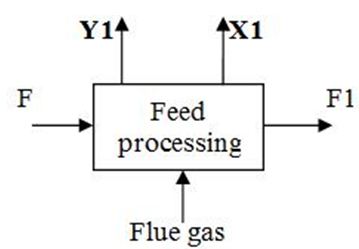

A) Feed Processing

The function of this system is to take the feed, process it and make it suitable for the pre-heater. Accordingly, this subsystem comprises sieving, grinding or drying or both (depending upon the raw material) storage and conveying to the feed pre-heater.

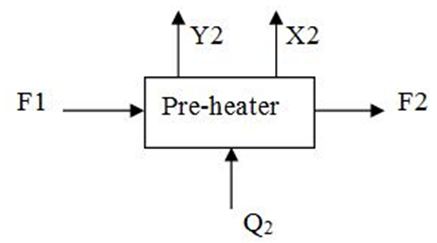

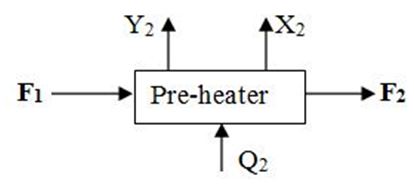

B) Pre-heater

The function of this component is to heat the pre-processed feed to the desired temperature by circulating the heat transfer medium and, finally, to convey the preheated material to the briquetting machine. During this stage there is no material loss but some moisture is removed from the feed due to heat gained from the furnace.

• Two units of each 750 kg/h (i.e., Feed = 1500 kg/h)

• Working time = 20 hours/day

• Annual working time = 245 days/year

• Heating value of coffee husk = 4200 kcal/kg

• No heat is required for drying coffee husk

• Furnace efficiency = 90%

• Specific heat of coffee husk at 5% moisture = 0.37

• Initial temperature = 30 ºC

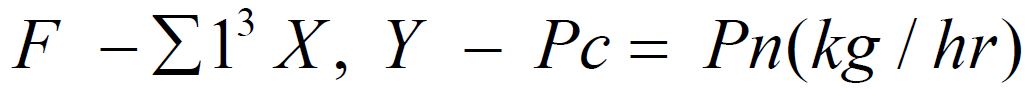

The overall material balance is given by the following equation:

Where, F = feed rate with xf moisture content

X1,2,3= moisture loss from components 1, 2 and 3

Y1,2,3= material loss from components 1, 2 and 3

PC = number of briquettes used in furnace

Pn = net production of briquettes

xf, xf1, xf2, xf3= moisture content of different streams

Material balance on feed processing

Assuming 1% loss of material at (xf)1 moisture content,

Output (F1) = 0.99 (F-X1) with (xf)1 moisture content

F1= 0.99(1500kg/h - 0) = 1485kg/h

• Loss of material (Y1) = F – F1, with (xf)1 = 0.1 moisture content

Y1 = 1500kg/h – 1485kg/h = 15kg/h

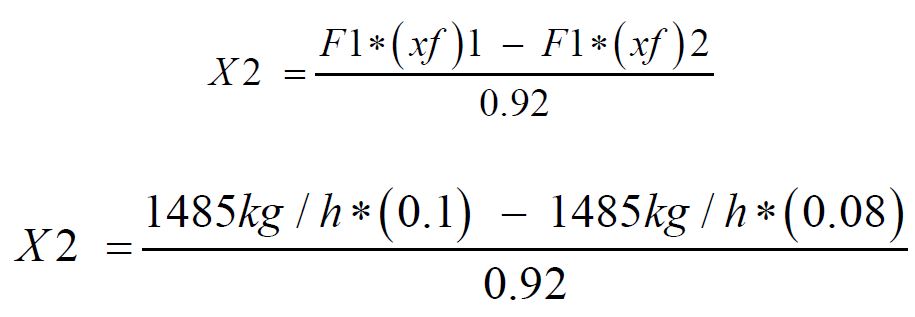

Material balances on preheating

In this section the biomass is heated to about 100 ºC. About 2% loss of moisture i.e. from 10% to 8% is expected.

Input (F1) = 1485kg with (xf)1 = 0.1 moisture content and From the assumption (xf)2 = 0.08

• Loss of moisture (X2); F1 = F1 * (xf)1 – (F1 – X2) (xf)2

X = 32 kg/h

Output (F2) = F1- X2

F2 = 1485kg/h – 32 kg/h

F2 = 1453 kg/h

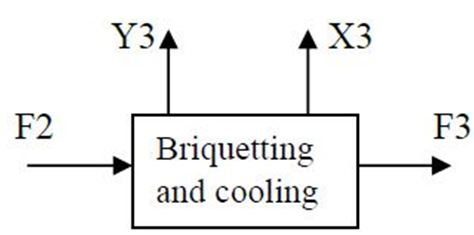

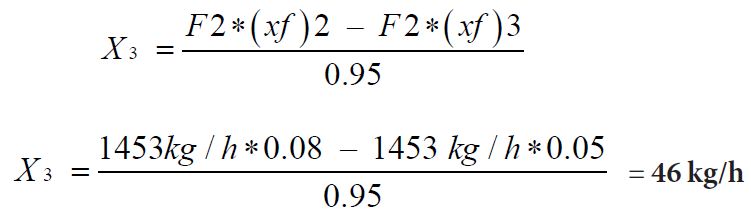

Material balance on briquetting and cooling subsystem

In this subsystem, the moisture is further expected to reduce from 8% to 5% and the direct loss of material is assumed to be 1.1%.

Input (F2) = 1453 kg/h with xf2 = 0.08

• Loss of material due to loss of moisture = (xf)2* F2 - (F2 - X3) (xf)3

• Direct loss of material (Y3) = 0.011(F2)

Y3 = 0.011*1453 = 16kg/h

Output (F3) = F2 – X3 – Y3

F3 = 1453 kg/h – 46 kg/h – 16 kg/h = 1391 kg/h

The material is heated up to 100 ºC and there is loss of moisture from 10% in feed to 8% in the output.

Heat required in pre-heater (Q2) = F1*Cp (Tf – Ti) + X2*hfg

hfg = hg – hl; hfg = 560 kJ/kg

Therefore, Q2 = F1 * 0.37 (100 – 30) k + X2 * 560 kJ/kg

Q2 = 1485 * 0.37(70) + 560 kJ/kg * 32.3 kg/h

Q2 = 56549.5 kJ/h = 57 MJ/h

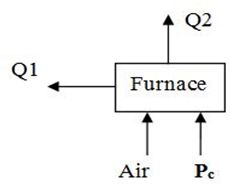

Assuming 50% heat going for preheating and the remaining 50% accounted for by losses in flue gases (40%) and losses due to radiation in oil circulating system (10%).

Thermal energy output from the furnace

Qout = (Q1 + Q2)

Qout = 2 * 56549.5 = 113,099 kJ/h

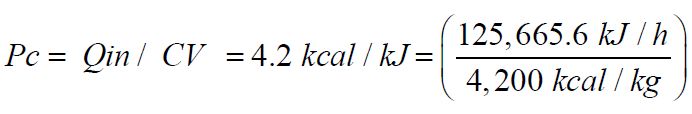

Thermal energy input in the furnace, (Qin) = (Qout) / η Qin = 113,099 / 0.9

Qin = 125,665.6 kJ/h = 126 MJ/h

The number of briquettes required in furnace for preheating having heating value of 4200 kcal/kg

Qin = Pc * CV Where, CV is calorific value of coffee husk

Pc = 126 kg/h

Net product (Pn) = F3 – Pc

Pn = 1391 kg/h – 126kg/h

Pn = 1265 kg/h; Where Pc is the number of briquettes used in the furnace.

Electricity and water are the two major utilities required by the plant. Assuming that 40% water is needed for mixing and for washing and other purposes it is assumed to 60% of the water used for mixing and thus, totally be 4704m3/yr. The unit cost per m3 is 7.00 birr then the total cost for water is 32,928 birr and 117,072 birr/yr for electricity and others. The total annual cost of utilities is estimated at Birr 1,50,000.

• T.I.C = W.C + F.C.I

Purchased equipment cost = 25% of F.C.I =1,200,550 birr

Therefore, F.C.I = (1,200,550*100)/25 = 4,802,200 birr

T.I.C = 15% of T.I.C + F.C.I

T.I.C = F.C.I/0.85

T.I.C = 4,802,200/0.85

T.I.C = 5,649,647 birr

• W.C =15% of T.I.C

W.C = 0.15 * 5,649,647 = 847,447 birr

• Depreciation = T.I.C/service life (5 yr)

= 5,649,647/5 = 1,129,929 birr/yr

• We set a unit selling price of briquette is 1500 birr/tonne

• Annual produced briquette = 1265kg/h * 20h/day * 245day/yr = 6,198.5 tonnes/yr Total annual income is found to be 6,198.5tonnes/yr * 1,500 birr/tonne = 9,297,750 birr/yr

Profit = annual income – total operating cost – depreciation

• Return on investment (R.O.I)

Yearly profit = 9,297,750 – 3,394,339 – 1,129,929 = 4,773,582birr/yr

Np = yearly profit (1 – tax rate (ø)) where, ø = 30% = 0.3

Np = 4,773,582 birr/yr (1 – 0.3)

Np = 3,341,507 birr/yr

• Return on investment (R.O.I)

(R.O.I) = Np/T. I.C

R.O.I = 3,341,507 /5,649,647 = 0.59 = 59%

The minimum return on investment (R.O.I) is 15% therefore 59% is greater than the minimum acceptable R.O.I so that, the project is feasible.

• Payback period (PBP)

PBP = (F.C.I – Vs) / (Np + depreciation)

PBP = (4,802,200 – 0) / (3,341,507 + 1,129,929)

PBP = 1.07 yr

Carbon Emissions

The use of wood is highly regarded as a fuel because it has the potential to be environmentally neutral, in that if wood is replaced at the same rate it is used then the amount of carbon released would be negated by the new trees. Where the consumption is greater than the supply as in most cases, there is an overall increase in carbon emissions.

The savings in fuel wood demand would therefore have a similar impact on reducing carbon emissions. The reduction in actual carbon released would not change significantly because the combustion of wood and briquettes would release similar quantities into the atmosphere. However, a reduction would occur because more trees are left standing to absorb more carbon. Based upon the quantities of trees saved by substitution with briquettes the carbon emissions would be lowered [6-8].

Reduction in Farmers’ Incomes

The coffee husk briquettes will directly replace wood. Whilst this has important environmental impacts the reduction in the demand for fuel wood will adversely affect farmer’s incomes. Farmers often rely upon tree cutting to supplement incomes particularly at occasions when additional monies are required to pay school fees, medical costs weddings and funerals.

The main factors that affected density at constant pressure are the quantity and type of binder used and the particle size of the coffee husk. The densities of the smaller particle size (3mm) with 45% molasses and clay are 833.3 kg/m3 and 909 kg/m3 respectively.

The combustibility increases with the increase in density for the same binding agent used. Briquette produced from coffee husk-molasses shows better combustibility than coffee husk clay. Clay has better binding capacity than molasses but it exhibits higher ash content. When briquettes produced at plant level could reduce large mass of trees from deforestation, since due to its high calorific value. Briquettes produced through binder less technology are more economical and convenient to handle, transport and store.

As we went through this study, we can get some points those have to be recommended;

➢ The combustibility of briquettes increases as the density increases but the optimum point has to be further studded.

➢ The project work mainly gives emphasis only for coffee husk but there are plenty of agro- residues those will be convenient for briquette, like maize stocks require study.